Resist of the month Juli 2015: Process-adapted two-layer resist AR-BR 5460

Resist of the month Juli 2015

Process-adapted two-layer resist AR-BR 5460

The bottom resist AR-BR 5460 has already been used for a decade in combination with positive (e.g. AR-P 3510) or negative resists (e.g. AR-N 4340) for a large variety of lift-off applications. Process: The non-light-sensitive bottom resist AR-BR 5460 is initially coated and tempered at 150 °C. The respective photoresist is then applied onto the bottom resist by spin deposition und dried as usual at 95 °C. After UV-exposure and development, the desired undercut is formed according to the adjusted development rate of the bottom resist. These structures allow a simple realisation of lift-off processes.

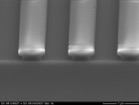

Undercut with negative resist

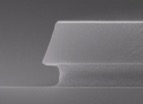

Undercut with the standard system AR-BR 5460/AR-P 3510 (different development times)

Processes however often vary considerably between the users. The influence of parameters like the substrate, resist, developer, tempering regime, structure size and film thickness demand a process optimisation. To support our customers in this respect, we conducted several studies with modifications of the bottom resist. The most important parameter in this context is the development rate, since this factor determines the achievable undercut.

The diagram shows different development rates of four AR-BR 5460-samples in dependence on the novolac fraction at different softbake temperatures:

Diagram: Course of development rates

For the sample with 15 % novolac, the dissolution rate for example ranges from 155 nm/s at 150 °C to 40 nm/s at 170 °C. With a broad selection like this, the optimum parameters for every technology can be found.

This high flexibility prompted us to select the modifications of AR-BR 5460 as resist of the month July.