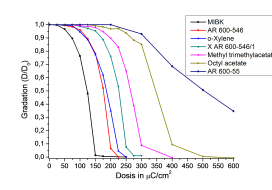

To evaluate the suitability of various developers for CSAR 62, Dr. Lothar Hahn (Karlsruhe Institute of Technology (KIT), Institute of Microstructure Technology) kindly provided various substrates which had previously been exposed to 100 kV e-beam irradiation (dose variations). The substrates were developed for 60 s in different standard developers and other solvents (indicated is in each case only the main solvent as e.g. MIBK, but not minor additions of other solvents), developed, and the development was stopped in IPA. The layer thickness was scanned using a Dektak 150. If the measured layer thickness divided by the respective initial layer thickness (D/D0) is plotted against the radiation dose, characteristic gradation curves for each developer are obtained. The steeper the curve, the higher is the contrast of the developer used. Weaker, high-contrast developer cause no or only low dark erosion (development of unexposed areas). In the case of AR 600-546 (amyl acetate) and X AR 600-546/1 (hexyl acetate), an additional rinsing step for 10 s with pure MIBK was conducted after development prior to the stopping with IPA to ensure a complete, particle-free development.

Dose variations for CSAR 62 (AR-P 6200); gradation curves of selected, high-contrast developers, SB 180 °C, film thickness: ~240 nm, 100 kV, development time 60 s each at 21.5 °C, stopper IPA.

Of all investigated high-contrast developers, MIBK turned out to be the strongest developer with a dose to clear of about 150 µC/cm2. The developers o-xylene and AR 600-546 (standard developer) yield comparable sensitivities of about 230 µC/cm2, whereby amyl acetate leads to a higher contrast than o-xylene. The solvents methyl trimethylacetate and octyl acetate also provide a high-contrast development, are however significantly less sensitive than the standard developer. Developer AR 600-55 which is generally used for PMMA films is not suitable for CSAR 62, since even at a dose of 600 µC/cm2 no complete development was observed.

Higher sensitivity values can generally be obtained if the development time is extended to 3 minutes. The contrast is in this case slightly reduced since the development process begins already at lower exposure doses (earlier onset).

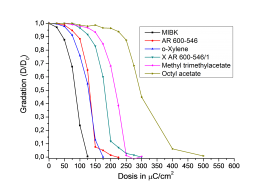

Dose variations for CSAR 62 (AR-P 6200); gradation curves of selected, high-contrast developers, SB 180°C, film thickness: ~240 nm, 100 kV, development times 60 s each at 21.5 °C, stopper IPA.

If strong developers are used for the development of CSAR 62, the resulting contrast is lower, but at the same time the sensitivity increases. The writing times can thus be reduced in particular for larger exposed areas, but a considerable amount of dark erosion has to be taken into account.

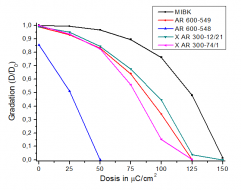

Dose variations for CSAR 62 (AR-P 6200); gradation curves of selected strong developers (reference MIBK), SB 180 °C, film thickness: ~240 nm, 100 kV, development times 60 s each at 21.5 °C, stopper IPA.

AR 600-548 showed the highest sensitivity of 50 µC/cm2, and the dark erosion can substantially be reduced if shorter development times are chosen. The strong special developer X AR 300-12/21 (containing PGMEA) causes a lower dark erosion as compared to AR 600-548 and is approximately as sensitive as the standard developer AR 600-549 (dose to clear of about 125 µC/cm2). Also the ethylbenzene-based developer X AR 300-74/1 is well suited for a sensitive development of CSAR 62 (dose to clear < 125 µC/cm2). Generally are higher sensitivities observed if the development time is extended to 3 minutes; the dose to clear is significantly reduced.

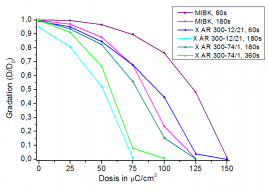

Dose variations for CSAR 62 (AR-P 6200); gradation curves of different strong developers, SB 180 °C, film thickness: ~240 nm, 100 kV, development times 60 s and 180 s in comparison (21.5 °C), stopper IPA.

If developer X AR 300-12/21 is used, a low dark erosion of about 5 % is observed at a development time of 3 minutes. The influence of the development time on the sensitivity was investigated in more detail for the standard developer AR 600-549.

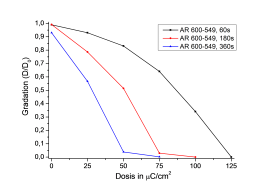

Dose variations for CSAR 62 (AR-P 6200); gradation curves for AR 600-549, SB 180 °C, film thickness: ~240 nm, 100 kV, development times 60 s – 360 s each at 21.5 °C, stopper IPA.

If the development time is extended from 1 minute to 6 minutes, the dose to clear can be reduced by more than half from 125 µC/cm2 to approximately 50 µC/cm2. Despite the very sensitive development, the dark erosion of about 7 % is comparatively moderate. Within 3 minutes of development time, no significant dark erosion occurs.

Especially in the case of thin resist layers, the process window is small if strong developers are used. Even only moderate dark erosion has a much greater impact in percentage terms when thin layers as compared to thicker layers are concerned. The dark erosion can be significantly reduced by lowering the developer temperature by a few degrees, as shown in the following for AR 600-548 as example.

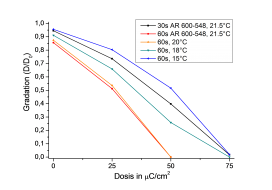

Dose variations for CSAR 62 (AR-P 6200); gradation curves for AR 600-548 in dependence on the developer temperature, SB 180 °C, film thickness: ~240 nm, 100 kV, stopper IPA.

While at room temperature a dark erosion of just below 15 % is observed within 60 s, this rate is reduced to only 5 % if the development step is carried out at 15 °C. At the same time, the dose to clear is reduced from 50 µC/cm2 to approximately 75 µC/cm2, and the contrast increases slightly.

Overview E-beam positive