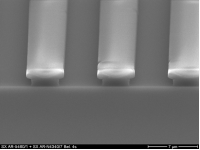

Positive two-layer systems have been on the market for a long time (see positive two-layer lift-off systems). Now there are also versions with negative resists as top resist. The greatest advantage of this innovation is the higher thermal stability of negative resists. The negative two-layer system SX AR-P5460/1 + SX AR-N4340/6 yields a distinct undercut and generates straight edges in the bottom layer, which is not self-evident, given the isotropic etching behavior (see fig. 1).

Fig. 1: Undercut generated with the negative two-layer system SX AR-P5460/1 + SX AR-N4340/6

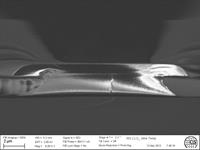

For even higher temperature stress, a thermostable negative resist was developed (→Temperature-stable negative resist). This resist shows promising results as top resist. In a relatively speedy manner, it was possible to optimize this two-layer development and generate the undercut. For this purpose, resists of the series AR-N 4300 were modified (copolymer from PMMA and polyhydroxystyrene instead of novolak) and the bottom resist AR-P 5400 was varied additionally. The resist SX AR-N 4340/10 is clearly more thermoresistant than the positive resists. The figure displays the two-layer system after development and a thermal treatment at 200 °C. The negative resist shows no interference whatsoever by the tempering step.

Fig. 2: Undercut after thermal treatment

Overview Photoresists- Negative