Development of PMMA films

PMMA films can only be developed with solvent-based developers. Aqueous-alkaline PMMA developers will not attack PMMA – PMMA is even used as protective coating in the presence of strongly alkaline solutions (→ protective coating AR-PC 503 and AR-PC 504 for KOH etchings).

For the standard conditions of PMMA e-beam lithography, generally developers composed of MIBK and isopropanol are recommended. Two concentrations turned out to be advantageous in this respect: 3 parts of isopropanol to 2 parts of MIBK (e.g. AR 600-55) and 3 parts of isopropanol to 1 part of MIBK (e.g. AR 600-56). AR 600-55 is the stronger developer, which means that exposed PMMA layers are developed much faster. The less strong AR 600-56 provides a slightly higher contrast.

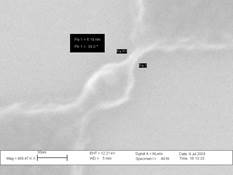

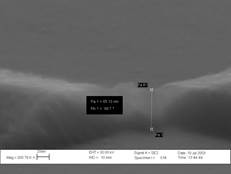

Developer variations are manifold in this field. A few users prefer pure MIBK for patterning, which is a quick process requiring however a careful coordination of procedures. Due to the speed of the reaction, the process window is quite narrow. In contrast, e-beam operators increasingly use pure isopropanol as developer, in a few cases even isopropanol-water-mixtures. Even though the development time is reduced in this case, the sensitivity is only marginally lower (by a factor of 2 – 3) as compared to a normal development. On the other hand, a far greater process window is obtained by these means. Dosage differences by a factor of 2 have no influence on the structural quality. In the case of a faster development, a deviation of only 10 % may have major consequences. IPA-developers are therefore especially employed for the generation of high-resolution structures. Using for example AR-P 671.02 and IPA as developer, a bridge of 6.2 nm was produced (see image).

A 6.2 nm gap at a resist film thickness of 65 nm, aspect-ratio of 10

Overview General-Process Informations