Dependence of the development speed of novolacs on the developer strength

For multi-layer applications in e-beam lithography, Allresist offers the highly versatile bottom resist AR-BR 5460/5480. The removal rates of the bottom layer can easily be specifically adjusted by slightly changing the softbake temperature and the developer strength. The removal rates are however in most cases too high for very thin layers. An alternative offer novolac resists. Pure novolac layers show a very similar behaviour, but the development speed can in this case be adjusted at a significantly lower softbake temperature. This variant is particularly suitable for lift-off e-beam applications with extremely thin layers < 50 nm, since very low development rates in a range of 0.2 - 1 nm/s can precisely be defined and a well-defined undercut can accordingly be produced.

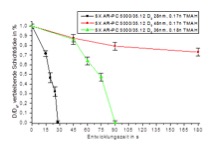

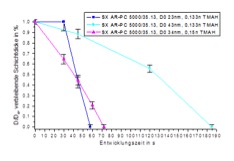

Very thin layers of < 50 nm of novolac resists SX AR-PC 5000/35.12 and SX AR-PC 5000/35.13 were developed after a softbake at 95 °C with TMAH developers in various concentrations. The film thickness was then measured after defined intervals with a profilometer (Dektak 150). Striking is the unexpected dependence of the development rate on the layer thickness. Thinner layers (< 30 nm) surprisingly show a significantly higher removal rate than slightly thicker layers, which has to be taken into account in the design of experiments.

Development curve of SX AR-PC 5000/35.12, 13 in TMAH developers with varying strength

Overview E-beam Positive