Photoresists are in particular used in microelectronics and microsystems technologies for the fabrication of µm- and sub-µm structures. Allresist provides a broad range of different resist types which cover a wide range of applications:

Photoresists produced by Allresist like e.g. AR-P 1200 (spray resists), AR-P 3100, 3200, 3500, 3700 are composed of a combination of film-forming agents such as e.g. cresol novolac resins and light-sensitive components such as e.g. naphthoquinone diazide (NCD), which are dissolved in solvents such as e.g. methoxy propyl acetate (equivalent to PGMEA). The addition of a light-sensitive component to the alkali-soluble novolac leads to a reduced alkali-solubility. The NCD-groups block the OH-groups of the cresol novolac resigns; the alkali-solubility decreases (inhibitory effect). After exposure at 308 – 450 nm (UV range) using an exposure mask, the light-sensitive component is converted into the respective indene carbonic acid derivative, the blockage is released and the alkali-solubility of positive resists is thus enhanced by a factor of 100. After development, only those areas which were protected by the mask remain, while exposed areas are detached. The refractive index of novolac-based resists is in a range between 1.58 – 1.63. After development, only areas protected by the mask remain while irradiated areas are dissolved. Photoresists provide an excellent protection against liquid etch media with pH values between 0 and 12.

Negative photoresists like AR-N 4200, 4300, 4400 are composed of novolacs and bisazides (4200, no CAR) or novolacs, acid generators and amine components (4300, 4400, CAR) dissolved in safer solvents like e.g. methoxypropyl acetate (PGMEA). (CAR = Chemically Amplified Resist). The chemical amplification is based on the formation of acids during irradiation and a subsequent cross-linking of amine components with the novolacs. Since acids (protons) are continuously formed during the crosslinking reaction, each proton can induce many cross-linking events which results in a high sensitivity.

After exposure and a subsequent tempering step, the composition of CAR leads to a cross-linking of the exposed negative-tone resist film. Irradiated areas are consequently rendered insoluble and remain after development, while unexposed areas are still soluble and dissolved by the developer.

Thick negative films up to 200 µm can be produced with CAR 44 (AR-N 4400). These resists which are highly sensitive in a range between 300 – 440 nm and to synchrotron radiation provide excellent structural quality. Layers and structures up to 100 µm can be realised with photolithography.

Image reversal resists for example resists of the AR-U 4000 series; positive resists with an additional amine component. Depending on the manufacturing process, positive or negative images can be generated. For the positive mode, exposure and development is carried out as usual for positive resists. Negative images are produced if an additional tempering step and flood exposure of the entire surface is performed after image-wise exposure ( Question 13).

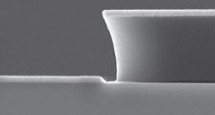

Resists for lift-off applications are positive resists AR-P 5300 and the two-component resist system AR-BR 5400/AR-P 3510. Lift-off (evaporation and sputtering of metal) is also possible with negative resists AR-N 4200, 4300 and 4450 as well as with the image reversal resists AR-U 4000. In all cases, an undercut resist edge has to be generated, so that the resist is not dissolved by the remover any further than the metallised edge after metal deposition.

Undercut structure

Protective coatings like AR-PC 500 and 5000 are offered by Allresist for a large variety of applications, e.g. for the backside protection of processed wafers during KOH and HF etchings, for a mechanical protection during transport, or as insulating layer. A special protective coating is Electra 92 (AR-PC 4010, 5091), which is conductive and used for e-beam lithography. Protective coatings are not light-sensitive and cannot be patterned if used alone. They can however be patterned with photoresists within the context of a two-layer system.

Allresist also produces a wide range of special resists, e.g. electroplating-stable resists like SX AR-P 5900/4 for applications performed at a pH-value of 13.

For hydrofluoric acid etchings and BOE-processes (up to 5 % HF), the 5 µm-resist AR-P 5910 (formerly X AR-P 3100/10) offers considerably better adhesion properties than all other photoresists.

For a patterning of glass/SiO2 substrates in concentrated HF, the positive-tone two-component system SX ARPC 5000/40 – AR-P 3540 T or the negative-tone two-component system SX AR-PC 5000/40 –AR-N 4400-10 is recommended. The upper photoresist layer is initially developed under aqueous-alkaline conditions before the lower SX AR-PC 5000/40 film is developed with solvents.

AR products are available both for the deep UV range of 240 – 300 nm (AR-N 4200, 4300) as well as for the long-wavelength exposure range up to 500 nm (SX AR-P 3500/6).

Thermally stable resists up to 400 °C are the polyimide resists SX AR-PC 5000/80 and SX AR-P 5000/82 and SX AR-P 3500/8 (PHS).

Overview Photoresist FAQs