January 2024: Electra 92 established on the market – AR-PC 5092.02

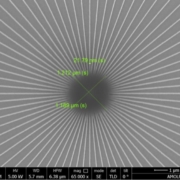

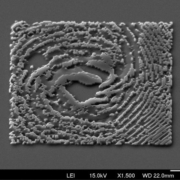

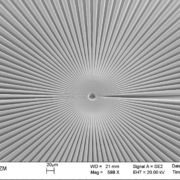

At AMOLF, Electra 92 was applied to HSQ deposited on a 40 nm thick SiO2 layer of a silicon wafer. Due to its highly hydrophobic surface, HSQ is particularly challenging. A specially adapted version of Electra 92 was required for this task.