Since problems may occur when PMMA protective coatings are applied, new ideas emerged how to optimise the coating properties of these resists. So far, protective coatings tend to show under certain circumstances the so-called “cotton candy effect” during spin coating, which means that fine PMMA threads are formed.

Now a PMMA test sample with lower molecular weight as compared to currently available polymers was developed which significantly reduce the cotton candy effect. First samples of these new, safer solvent-based protective coatings with optimised application properties will be available from the beginning of 2015.

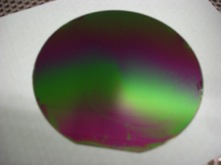

Fig. 10 Wafer with SX AR-PC 5040/1 after 6h etching in 30% KOH at 85°C