Polymethyl methacrylates (PMMAs) are widely used e.g. in electron beam lithography. PMMAs are produced by polymerisation of methacrylic acid esters in the presence of radical starters. PMMA layers show a very good adhesion to silicon, glass and the majority of metals. For the fabrication of positive-tone electron beam resists, Allresist uses short-chain (50k), long-chain (950k) and PMMAs with intermediate chain length (200k, 600k). The short-chain PMMA possess an approximately 20 % higher sensitivity as compared to the long-chain polymer. PMMA is furthermore characterised by an excellent resistance to most acids and strongly alkaline etch media like e.g. 50% aqueous KOH and is thus utilised as starting material for our protective coatings AR-PC 503/504 (new: AR-PC 5040 in safer solvent).

Poly(methylmethacrylate- co- methacrylic acid) (PMMA co MA) is a copolymer composed of methacrylic acid and methacrylic acid methyl ester. Allresist uses a copolymer with 33% of methacrylic acid as starting material for the electron beam resists AR-P 617 . This polymer has very good adhesion properties to silicon and glass. The sensitivity in e-beam lithography applications is higher by a factor of 3-4 as compared to PMMA polymers which results in an accordingly higher contrast. If PMMA co MA is heated to temperatures above 180°C, water is eliminated from the polymer under formation of methacrylic acid anhydride, an effect which is responsible for the increase of sensitivity. If used in a two-layer process, PMMA co MA is furthermore well suited for the generation of lift-off architectures.

Poly(α-methylstyrene- co- methacrylic acid methyl ester) (PMS co Cl-MMA) is a copolymer composed of α-methylstyrene and methacrylic acid methyl ester. Allresist uses this copolymer for the highly sensitive electron beam resists CSAR 62 (AR-P 6200) . The polymer shows very good adhesion properties and a very high plasma etch stability which is comparable to novolacs. Compared with the PMMA polymers, the sensitivity of CSAR 62 is 3-15 times higher, which results in a higher contrast. (PMMA normally 5-7, but CSAR 62 with developer X AR 600-54/6 even >14!). Furthermore, CSAR 62 is ideally suited for the fabrication of lift-off architectures and can also be used in multilayer processes with PMMA and/or PMMAcoMA 33 for the composition of T-gate structures.

Polystyrenes (PS) are characterised by a high chemical resistance to concentrated acids, bases as well as long-chain hydrocarbons and aldehydes. In addition, polystyrenes have very good insulating properties and a high plasma etch stability. Allresist utilizes polystyrenes for the fabrication of negative resists which can be structured both by UV light and by electron beams.

Polyimides (PI) are applied as sensor material, as protective coating or as insulating layer. Resists provided by Allresist contain the finished polyimide, a high-temperature curing is not required. Due to the high melting point, polyimides are particularly well suited for high-temperature applications > 400 °C. Allresist also offers polyimides for structuring as negative-tone polyimide resists SX AR-N xy and as positive-tone polyimide resists SX AR-P 5000/82.7. Structures generated with these resists show an excellent stability during plasma etching and implantation processes. The negative polyimide resists SX AR-N xy can also be structured by laser exposure up to the NIR-range and by electron beams.

Polyhydroxystyrenes (PSOH) are utilised as insulating layer in organic transistors and for LCD displays. Polyhydroxystyrenes are well suited for a use as photoresist just like novolacs, but possess a higher thermal stability up to 300°C. Polyhydroxystyrenes are thus the preferred choice for applications in which metals are vapour-deposited. Allresist offers polyhydroxystyrenes as structurable negative resist. A structuring is also possible by laser exposure up to the NIR-range and by electron beams.

Poly(hydroxystyrene- co- methyl methacrylate) (PSOH co MMA) is a copolymer composed of 4-vinylphenol and methacrylic acid ester. Just like the polyhydroxystyrenes, PSOH co MMA is characterised by very good insulating properties and a high thermal resistance and can also be developed under aqueous-alkaline conditions. As compared to polyhydroxystyrene, PSOH co MMA shows lower moisture absorption from the air. Allresist offers PSOH co MMA as structurable negative resist.

Long-chain hydrocarbons which are obtained during the rectification of oil possess an excellent resistance to a large variety of corrosive chemicals like e.g. concentrated bases or concentrated hydrofluoric acid. Due to this property, hydrocarbons are used in the special protective coating SX AR-PC 5000/40. In combination with photoresists AR-N 4400-10 and AR-P 3250 , also defined resist structures can be generated in a two-layer process. By these means, structures can be etched with hydrofluoric acid into glass substrates (see AR-NEWS, 23 rd issue).

Fluorinated hydrocarbons are characterised by excellent isolating qualities. They are used in the special protective coating SX AR-PC 5060 (F-Protect). The resist consists of a perfluorinated amorphous copolymer, dissolved in a solvent mixture of perfluortri-n-butylamin and perfluor-n-dibutylmethylamin (Fluorinert™ FC-40). The resist layers are characterised by a low refraction index, a very high optical transparency, excellent isolating qualities and outstanding stability against solvents and etching agents. Especially the very good isolating qualities and the high thermal stability, the decomposition of the polymer does not begin under approx. 350°C, are crucial properties for an application for organic field-effect-transistors.

Novolacs are phenol resigns with a formaldehyde-phenol-ratio of less than 1:1 which are obtained by acidic condensation of methanal and phenol. In combination with light-sensitive compounds like e.g. diazon aphtoquinone (DNQ), novolacs are used in microelectronics as photoresist for micro-structuring.

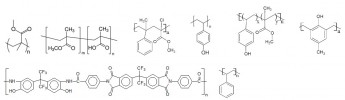

Fig.: Polymers used for lithographic applications, from left to right: PMMA, PMMA co MA, PMS co Cl-MMA, PSOH, PsOH co MMA, novolacs, PI, PS

|

Polymer |

Brechzahl h |

Glastemp. TG in °C |

Schmelztemp. in °C |

Dichte g/cm3 |

Löslichkeit |

|

PMMA |

1,492 |

105 |

Decomp. 270 |

1,19 |

Well: acetone, NEP, MIBK, toluene |

|

PMMAcoMA 33 |

1,490 |

150 |

Decomp. 280 |

1,19 |

Well: acetone, NEP, PM |

|

Poly(a-methylstyrene-co-Cl-MMA) |

1,541 |

105 |

Decomp. >220 |

– |

Well: NEP, anisole, toluene, DEK |

|

Poly(p-hydroxystyrene) |

1,600 |

150 |

Decomp. 320 |

1,16 |

Well: acetone, PMA, ethanol |

|

Poly(p-hydroxystyrene-co-MMA) |

– |

– |

224 |

1,39 |

Well: acetone, PMA, NEP |

|

Polyimide

|

1,623 |

169 |

Decomp. >500 |

1,15 |

Well: acetone, PM, PMA, THF |

|

Polystyrene |

1.592 |

100 |

~240°C |

1,05 |

Well: acetone, CB, EB |

|

Long-chain hydrocarbons |

– |

– |

>140 |

1,02 |

Well: toluene, CB, EB |

|

Fluorinated hydrocarbons: Poly-1,1,2,4,4,5,5,6,7,7-decafluoro-3-oxa-1,6-heptadiene |

|

|

Decomp. >350 |

|

Well: Perfluorotributylamine |

|

Novolacs

|

1,61 |

80 – 100 |

120 – 140 |

1,16 |

Well: acetone, PM, PMA |

Table : Overview selected polymer properties