New aqueous-alkali soluble polymers may even outperform novolacs in certain features. Standard novolacs generally melt in a range between 120–140°C. The thicker the resist film, the higher is the impact of this feature on the resist structure. Ridges with a height of 10 µm often simply melt away at 130°C. A high thermal stability could prevent this problem which particularly occurs during ion or plasma etching steps.

Investigations with an aqueous-alkaline developable copolymer of PMMA and polyhydroxystyrene showed a high thermal resistance of these films. This polymer resulted in the chemically amplified negative resists SX AR-N 4340/7 after addition of acidifies and aminic cross-linkers. Emanating from the polymer polyhydroystyrene, the likewise sensitive and very thermostable resist SX AR-N 4340/6 could be developed as well. As expected for chemically amplified resists, these negative resists are very sensitive. In addition to the application as one-layer resist, it can also be applied for two-layer systems with bottom resist AR-BR 5480, in which defined undercut structures can be generated.

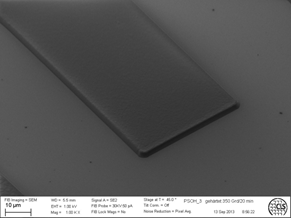

Tests performed to determine the thermal stability indicated no roundening of edges at a film thickness of 5,5 µm up to a temperature of above 300°C.

SEM micrograph of a structure of SX AR-N 4340/6 with smooth surface and sharp edges, tempered at 350 °C

Shrinkage dependent on temperature, measurement on Dektak 150

The structures of the resists withstand temperatures up to 350 °C accurate to shape. There is merely a maximum shrinkage of approximately 20 % due to sinter processes.

The copolymer is also succesfully applied for a positive resist version which is particularly well suited for high temperature applications and ion implantation processes (see SX AR-P 3500/8).

Overview Photoresists- Negative